Pulp Processing Foam Control & Antifoam for Paper Industry

The modern paper industry is a cornerstone of global communication and packaging, Achieving high efficiency and consistent quality in paper production heavily relies on managing process variables, among which foam control presents a significant challenge. From pulp processing to the paper machine and coating applications, unwanted foam can disrupt operations. This article provides an overview of why effective foam control using specialized antifoams is crucial throughout the pulp and paper value chain, and how INVINO delivers reliable foam control agents.

This article explores strategies for effective foam control using specialized antifoams. For an overview of INVINO’s tailored solutions for various process stages, visit our main Pulp and Paper Defoamers industry page.

Why Use Antifoam in Paper Making? Understanding Foam Hazards

Foam is an inherent challenge in paper making. Generated by lignin residues, sizing agents, coating binders, surfactants, and intense mechanical agitation, excessive foam negatively impacts the entire process:

- Reduced Efficiency: Slows down drainage on the paper machine, limits washing effectiveness in pulp processing, reduces screen room capacity, and lowers overall production speed. (

pulp processing foam controlis vital here). - Quality Defects: Leads to pinholes, spots, uneven formation, poor surface strength, and sheet breaks, compromising the final paper or board quality. Issues can arise even in specific applications like paper carton production if foam is not managed.

- Operational Problems: Causes pulp slurry overflows, pump cavitation, inaccurate sensor readings, and increased cleaning downtime.

- Increased Costs: Results in fiber/chemical loss, higher energy consumption (for pumping, drying), and increased consumption of other process chemicals.

Advanced Foam Control in Pulp Processing (Washing & Bleaching)

In the pulp mill, foam is often caused by lignin, resin acids, and high-temperature black liquor. Uncontrolled foam in pulp processing can lead to:

-

Soda Loss: Poor washing efficiency resulting in chemical waste.

-

Deposit Formation: Pitch and scale buildup on washers.

-

Pump Efficiency: Cavitation in filtrate pumps.

Our Solution: INVINO offers specialized High-Solid Silicone defoamers specifically designed for the Black Liquor Washing stage, ensuring excellent drainage and high temperature resistance.

Methods for Foam Control for Pulp and Paper

Managing paper foam control and pulp foam control involves various approaches:

- Physical Methods: Mechanical foam breakers or vacuum systems can help, but often have high energy consumption or limited effectiveness, especially against stabilized micro-foam.

.INVINO focuses on developing highly efficient defoamer for paper industry solutions. Explore our complete range here.

- Chemical Methods: The Role of Antifoaming Agents

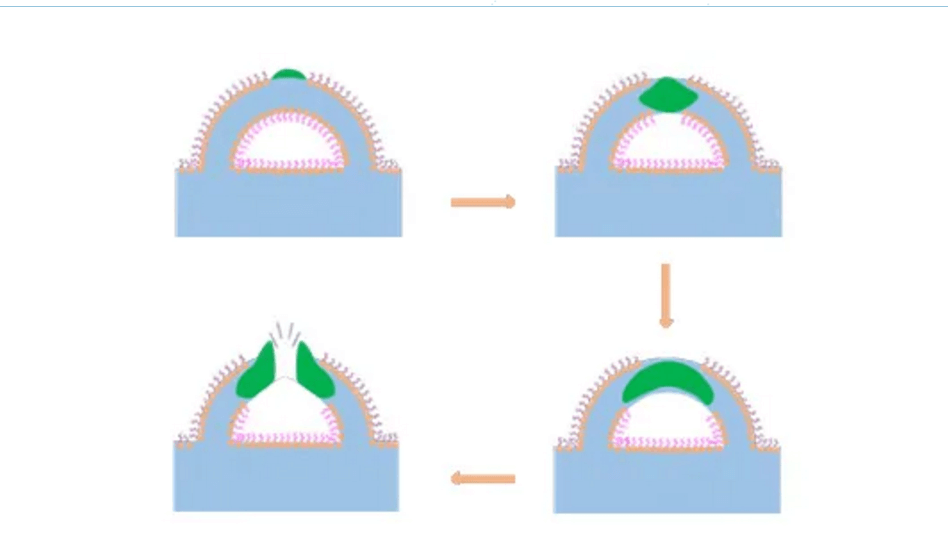

- This is the most common and effective approach. Antifoaming agents (also called defoamers) work by reducing surface tension and disrupting foam bubble stability.

- Key properties for an effective antifoam reagent in this industry include rapid spreading on the foam surface and incompatibility with the foaming medium. INVINO focuses on developing highly efficient defoamer for paper industry solutions.

The Benefits of Using Antifoam in Paper Production

The strategic use of high-quality defoamer for paper making offers significant advantages:

- Improved Efficiency: Faster drainage, higher machine speeds, reduced downtime.

- Enhanced Quality: Uniform sheet formation, reduced spots and defects, better printability and coating holdout.

- Cost Savings: Lower chemical/fiber loss, reduced energy consumption, optimized process chemical usage.

- Environmental Considerations: Modern antifoams, including options compatible with ecolabel requirements (antifoams for ecolabel), can contribute to more sustainable operations compared to alternatives or letting foam run rampant.

Key Considerations When Selecting Paper Industry Defoamers

Choosing the right paper industry defoamer is critical. Key factors include:

- Application Point: Needs differ significantly between pulp processing (e.g., paper pulping, washing, black liquor),papermaking wet-end, coating kitchen, or wastewater treatment.

- System Conditions: Stability under varying pH (acidic/alkaline), temperature, and shear conditions.

- Compatibility: Must be compatible with other papermaking chemicals (sizing agents, retention aids, dyes, coating binders) and not cause negative interactions.

- Low Deposit Tendency: Crucial to avoid spots, fisheyes, or felt/wire plugging.

- Ecolabel Compliance: Balancing foam control efficiency with ecolabel criteria. Options like our fatty alcohol defoamers are often preferred.

- Performance & Cost-Effectiveness: Balancing foam control efficiency with dosage rate and overall cost impact.

Development Prospects of Antifoam in the Paper Industry

The anti foaming agent market for the paper industry continues to evolve. Key trends driving development include demands for higher machine speeds, increased use of recycled fiber (which can increase foaming tendency), stricter environmental regulations (favoring antifoams for ecolabel compatibility), and the need for highly efficient, cost-effective foam control agents. INVINO is committed to ongoing R&D to meet these evolving market needs.

Effective foam control is indispensable for modern, competitive pulp and paper production. Selecting the right antifoam for paper industry applications significantly impacts efficiency, quality, and profitability. INVINO provides not only a wide range of high-performance defoamers but also the technical partnership to ensure you achieve optimal results across your entire papermaking process.

Contact INVINO today to discuss your specific paper foam control needs, explore our product range, or request a sample.”