Glyphosate Defoamer: Essential Agricultural Additives for Foam Control

Glyphosate, a cornerstone herbicide, relies heavily on adjuvants like surfactants to enhance its wetting, spreading, and penetration for effective weed control. However, these essential defoaming surfactants often cause significant foam issues during the production of glyphosate SL (Soluble Liquid) formulations and especially during tank-mixing and spray application. This article explains why an effective anti foaming agent for herbicide formulations, specifically a high-performance glyphosate defoamer, is crucial, and showcases solutions from INVINO.

Why Glyphosate Formulations Need Defoamers?

The introduction of surfactants needed for efficacy inherently leads to the generation of a large number of bubbles during production and use… This makes foam difficult to control and affects production efficiency… Therefore, adding a suitable agricultural defoamer like INVINO-2200 becomes the easiest way to ensure stable glyphosate SL formulation and application.

The sodium, ammonium and trimethylsulfonium salts of glyphosate are easily soluble in water. For glyphosate to achieve the weeding effect, it must be absorbed by the plant and enter the plant body. In this process, additives need to be added. The main function of the additives is to reduce the interfacial tension and contact between the droplets and the waxy layer on the leaf surface. Angle, make the droplets spread smoothly; increase the ability of droplets to penetrate the waxy layer of the leaf surface, so that the droplets can enter the plant body smoothly or promote the absorption of the droplets by the plant; make the droplets better dispersed and dispersed in the plant body fluid Conduction until the droplet reaches the life unit of the plant.

At present, the main additives used for glyphosate are: tallow fatty amine ethoxylate, alkyl polyglycoside, fatty alcohol ethoxylate, silicone, betaine, amino acids, anti-drift agents, anti-hardening agents, Synergist, etc. Glyphosate is a low-toxicity, broad-spectrum, high-efficiency non-selective post-emergence herbicide, which can be conducted in plants, but it can only be applied to foliage spraying to show herbicidal activity. The pros and cons of the herbicidal effect largely depends on the selection of suitable good additives to improve the herbicidal activity.

However, the introduction of additives caused a large amount of foam during the production and use of the glyphosate water agent, and a large amount of air was mixed in the process of adding the auxiliary agent to stir, thereby generating a large number of bubbles, because the introduction of surfactants, the The bubbles are extremely stable under the protection of surfactants, which is unfavorable to production and easy to produce punching. And the generation of a large number of bubbles makes the system density drop, which is not conducive to canning and affects production efficiency.so the easiest way is to add Agricultural antifoam to control foam.

INVINO-2200 Agricultural antifoam is used for glyphosate SL formulations as an anti-foaming agent, suitable for all water-based formulations.

Problems Caused by Foaming in Glyphosate SL Formulation

- Uneven Dilution & Application

- Waste of Active Ingredient & Formulation

- Handling Difficulties & Clogging

- Impaired Sprayability & Coverage

- Potential for Reduced Efficacy

Glyphosate Defoamer Test

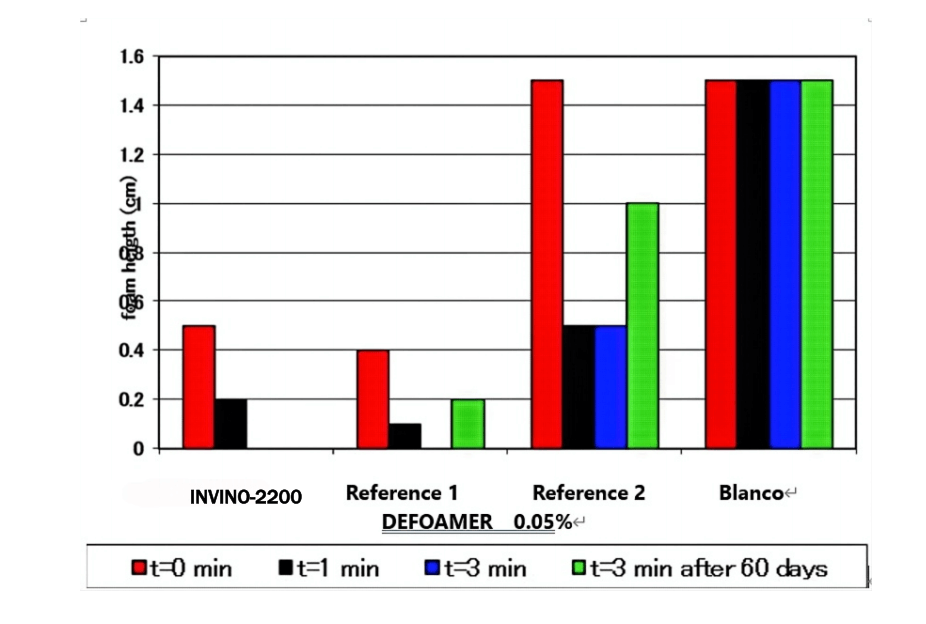

- INVINO-2200 is a high dynamic defoamer with low silicone content. It also maintains outstanding defoaming performance after storage, especially when it contains ionic surfactants.

- Glyphosate SL formula anti-foaming agent test formula

- Glyphosate IPA salt: 45,8 wt.-%

- Tallow amine contains 15 EO: 8,0 wt.-%

- Water: 46,12 wt.-%

Glyphosate SL formula anti-foaming agent dosage: 0.05%

Glyphosate SL formulation anti-foaming agent test results

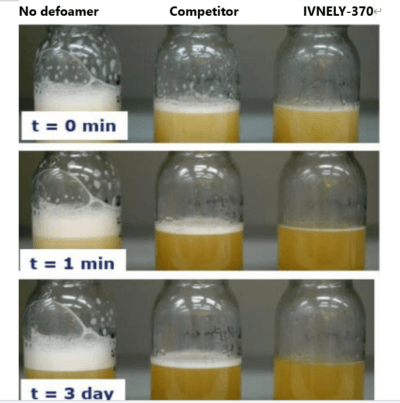

The defoaming effect of INVINO-2200 after storing in glyphosate SL formulation at 40°C for 3 days.

The defoaming effect of INVINO-2200 after storing the glyphosate SL formulation at 40°C for 3 days is shown below, demonstrating excellent long-term defoaming performance and persistence compared to references.

INVINO-2200 is specifically developed for glyphosate formulations, providing excellent long-lasting defoaming performance and stability directly within the concentrate. Choosing a high-quality, compatible glyphosate defoamer like INVINO-2200 ensures smoother production, easier application, and reliable efficacy for end-users. Partner with INVINO for advanced agricultural defoamer solutions.

If you have questions about controlling foam in glyphosate or other herbicide formulations, please contact INVINO for technical support, product details on INVINO-2200, or samples.