The Science of Dynamic Defoaming: Why Static Tests Are Not Enough for High-Speed Paper Machines

In the modern paper mill, efficiency is dictated by the speed of the machine and the stability of the wet-end chemistry. As paper machines push beyond 1,500 m/min, the physical behavior of foam changes. Traditional laboratory evaluations, often relying on simple static “shaking tests,” are increasingly failing to predict how a defoamer will perform on a high-speed production line.

This article explores the physics of Dynamic Defoaming and explains why high-shear stability is the only metric that matters for modern papermaking.

1. The Critical Flaw of Static Foam Testing

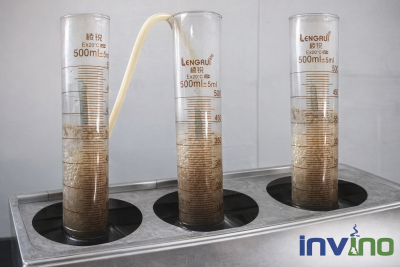

Most chemical suppliers use a "Graduated Cylinder Test" or a "Shake Test" to demonstrate defoamer efficiency. While these tests are useful for basic screening, they are fundamentally flawed for high-speed systems for three reasons:

- Zero Shear Stress: Static tests measure how quickly a defoamer breaks a surface bubble in a resting liquid. They do not account for the massive mechanical energy and turbulence found in the wire section.

- Equilibrium vs. Non-Equilibrium: On a paper machine, air is constantly being entrained through high-pressure sprays, creating a "non-equilibrium" state of continuous foam generation.

- Bubble Size Distribution: High-speed machines generate micro-foam (dissolved and entrained air), which requires a different chemical mechanism to eliminate than large surface bubbles.

2. Defining Dynamic Defoaming: The High-Shear Challenge

Dynamic Defoaming refers to the ability of an antifoam agent to maintain its surface-active properties while being subjected to intense mechanical forces. In a high-speed paper machine, the defoamer must survive:

- Centrifugal Pumps: Where high shear can physically "break" a weak defoamer emulsion, causing it to lose efficacy or create oil spots on the paper.

- Screening and Refining: Intense turbulence that requires the defoamer to rapidly re-spread across air-liquid interfaces.

- Pressure Variations: Rapid changes that force entrained air into the fiber matrix if the deaerator is not chemically optimized.

For processes requiring extreme stability, many engineers are turning to specialized silicone defoamers designed for high-end industrial applications.

3. Polyether Defoamers: The Solution for Dynamic Systems

While silicone-based defoamers are powerful, they can struggle with "plate-out" defects in high-shear environments. This is where Polyether Defoamers excel.

The Cloud Point Mechanism

As white water temperature rises, the polyether becomes insoluble, forming "defoaming seeds" that do not shear apart like traditional emulsions. This molecularly engineered stability ensures consistent performance throughout the wet end.

Superior Spreading Velocity

In a dynamic system, the time a defoamer takes to reach a bubble is measured in milliseconds. Polyether surfactants have a higher spreading coefficient compared to fatty alcohol anti-foaming agents, suppressing foam instantly at the headbox.

4. How to Properly Test for Dynamic Performance

To choose chemistry for 2026 standards, R&D managers should transition to Dynamic Foam Loop Testing focusing on these three metrics:

- Rate of Rise: Measuring foam height over time under high-speed circulation.

- Defoaming Persistence: Tracking how many pump cycles the defoamer can withstand before failure.

- Deaeration Speed: Measuring the density of the liquid to see how quickly micro-foam is removed.

For construction applications, a powder defoamer is often evaluated using similar dynamic standards to ensure structural integrity.

A packaging board mill experienced persistent pinholes using fatty alcohol. INVINO's Dynamic Foam Loop Test revealed a 70% efficiency loss after 5 minutes of high-shear pumping. By switching to a High-Molecular Weight Polyether Defoamer:

- Sheet breaks were reduced by 15%.

- Headbox air content dropped from 1.5% to 0.4%.

For unique systems, explore our OEM defoamer services for custom molecular engineering.

5. Conclusion

In 2026, papermaking is about managing air in motion. Relying on static tests risks chemical waste and paper defects. Utilizing shear-stable polyethers or specialized mineral oil defoamers ensures higher speeds with total stability.