Application of defoamer in PVC production

Depending on INVINO expert team with rich experience, we share an article about the application of defoamer in PVC production.

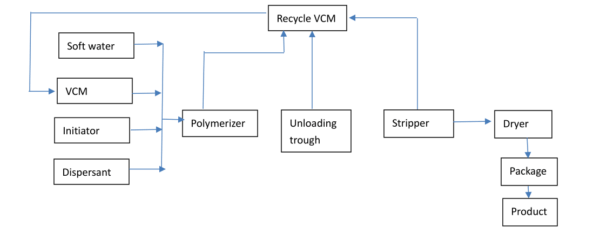

Due to particularity of the PVC production, we generally add defoamers in the following four process steps:

Defoamer in the process of preparing dispersion

HPMC and PVA must be prepared when they are used as suspending agents. Stirring is required during preparation, Therefore, the solution often foams, overflow of foam can cause the loss of dispersant, by the way, the height of the liquid level cannot be observed, so it is important to add defoamer controlling foam.

Defoamer in the polymerization process

“Wet bubbles” In the polymerization reaction, because the polymerization reaction system uses HPMC and PVA as dispersants which have certain surface tension. Foam will also be generated under the progress of stirring in the polymerization tank, these foams can be called “wet bubbles”. “Wet bubbles” which make VCM gas phase polymerization are generated above the liquid level of the reaction system, causing the inner wall of the kettle above the liquid level to stick to the kettle, and the adherents fall into the kettle, which can increase the black and yellow spots of the resin, it would influence the quality of Resin.

“Dry bubbles”.

In a kettle with a reflux condenser, in order to increase the cooling effect, a large amount of VCM gas phase passes through the liquid layer to the condenser during the reaction, and then condenses into a liquid state by the condenser and returns to the reaction system. In this process, it would produce a lot of foam with the vapor phase of VCM volatilizes. This process often occurs in the intense period of the reaction, and these foams can be called “dry bubbles”.

“Dry bubbles” and “wet bubbles” are eliminated with defoamers. Since the suspension reaction liquid is an unstable system, selecting a suitable defoamer will have a greater impact on the entire reaction process.

So how to add defoamer? it should be added by continuous dripping after 2h from the beginning of the reaction, and the defoamer should be diluted appropriately. Because a high concentration defoamer would damage the suspension system in the reactor, cause coarse particles, and affect the product quality of the resin.

Defoamer in the Operation of Stripper

When the reaction is completed, the slurry VCM is removed by stripping. Since it is generally carried out in a stripping tower, the slurry flows from the top of the tower to the bottom of the tower, while the steam from the bottom of the tower conducts sufficient heat exchange with the slurry. In this process, the slurry on each tray will produce foam. These foams will seriously hinder the volatilization of the slurry VCM and increase the power to remove the VCM. If the foam stays on the tower wall for a long time, it will produce “black and yellow particles”, which will affect the quality of the product.

In order to eliminate the generation of foam during the stripping operation. Defoamer is must be added, The defoamer should be diluted appropriately and added to the stripping equipment evenly, because the addition of high-concentration defoamer may cause excessive adsorption of PVC particles, which will affect the recovery and post-processing of VCM monomers. Therefore, use defoamer to dilute and then continuously drip. It can eliminate a large amount of foam produced during stripping, increase the recovery speed and speed up the recovery process.

Defoamer in PVC production of paste resin

Except for ordinary powdered PVC resin produced by suspension method. There is also a larger variety of PVC paste resin, which is mainly used for synthetic leather and latex products. It is necessary to add defoamer in the PVC paste resin.