High-Temperature Defoamer: How Much Heat Can It Withstand?

A high temperature defoamer is a critical chemical additive used to control foam in demanding industrial environments. These specialized agents, often referred to as high temperature processes antifoams, are essential in industries like chemical manufacturing, food processing, pharmaceuticals, and petroleum. Uncontrolled foam can disrupt production, reduce efficiency, and compromise product quality. While various defoamers exist, some optimized for specific needs (like finding a better dish defoamer at lower temperatures), many industrial applications require exceptional heat stability.

Among various defoamer properties, temperature resistance is paramount for these challenging conditions. A reliable high temperature defoamer, sourced from a knowledgeable high temperature defoamer factory like INVINO, must maintain its foam control effectiveness even under extreme heat. But the key question remains: how much heat can a high-temperature defoamer truly withstand? Let’s explore the specifics of their thermal stability.

How Does a High-Temperature Defoamer Work?

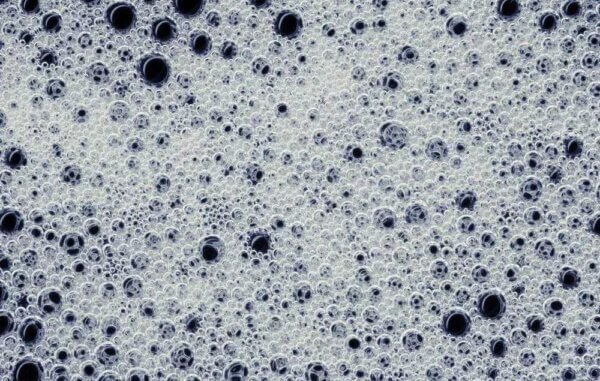

A high-temperature defoamer primarily functions by reducing surface tension at the gas-liquid interface, which destabilizes foam bubbles and causes them to break down. When introduced into a hot system, these high temperature processes antifoams must rapidly penetrate the foam structure, spreading to form a thin film that prevents gas entrapment and eliminates foam.

The crucial factor is maintaining this activity at elevated temperatures. The heat resistance of high temperature defoamers varies significantly based on their specific chemical composition, molecular structure, and the expertise involved in their production process (reflecting the quality from the high temperature defoamer factory). Many effective formulations rely on silicone chemistry due to its inherent thermal stability. Users often ask, “how much heat can silicone withstand?” – specially modified silicones used in these defoamers can be stable well into the upper limits mentioned below.

Typically, quality high-temperature defoamers can operate effectively in ranges from 80°C up to 250°C or even 300°C (176°F to 482°F/572°F). However, the specific maximum operating temperature will always depend on the precise formulation and the demands of the high-temperature process itself.

What Are the Different Types of High-Temperature Defoamers?

Silicone-Based High-Temperature Defoamers

- These defoamers have excellent thermal stability and can withstand temperatures up to 300°C (572°F).

- They are commonly used in petroleum refining, chemical processing, and high-heat manufacturing.

- Silicone-based defoamers not only eliminate foam effectively but also maintain stability at extreme temperatures, preventing decomposition.

Organic Polymer-Based High-Temperature Defoamers

- These defoamers have a lower temperature tolerance, typically between 150°C and 200°C (302°F to 392°F).

- They are often used in industries where high-temperature resistance is required but not as extreme as in petrochemical applications.

Mineral Oil-Based High-Temperature Defoamers

- These are effective at moderate temperatures but tend to degrade at extreme heat.

- Suitable for applications in food processing, wastewater treatment, and lower-temperature industrial processes.

How to Choose the Right High-Temperature Defoamer for Your Application?

When selecting a high-temperature defoamer, it is essential to consider the following factors:

3. Application-Specific Considerations

- Food Industry: The defoamer must comply with food safety regulations.

- Petroleum & Chemical Industries: Stability at extreme temperatures is critical.

- Pharmaceutical & Biotechnology: The defoamer should be non-toxic and highly efficient.

1. Temperature Requirements

- Identify the maximum operating temperature of your process.

- Choose a defoamer with a heat tolerance exceeding your system’s peak temperature.

2. Compatibility with Process Fluids

- Ensure that the defoamer is chemically compatible with your production materials.

- Some defoamers may react with certain chemicals, reducing effectiveness

4. Defoaming Efficiency and Residue Control

- A good high-temperature defoamer should eliminate foam without leaving residue that could interfere with the process.

- Residue buildup can lead to contamination or equipment malfunction.

Where to Find High-Quality High-Temperature Defoamers?

At INIVNO, we specialize in providing industry-leading high-temperature defoamers designed for various applications. Our advanced defoamer solutions are formulated to offer high efficiency, superior stability, and excellent heat resistance, making them ideal for demanding industrial environments.

A high-temperature defoamer plays a crucial role in industrial production, ensuring efficiency and product quality by controlling unwanted foam. Depending on the formulation, a high-temperature defoamer can withstand temperatures ranging from 80°C to 300°C, with silicone-based varieties offering the highest thermal stability.

When selecting a high-temperature defoamer, it’s essential to evaluate temperature resistance, chemical compatibility, and process-specific needs. If you’re looking for a reliable defoamer solution for extreme conditions, explore our expertly formulated defoamers at INVINO.

Recommended Reading:

By understanding how high-temperature defoamers work and why they are essential, you can optimize your production processes and ensure smooth, foam-free operations even in extreme heat conditions.