The surface condition and cleanliness of steel strips before annealing coating are crucial for ensuring the quality of the continuous annealing coating. During the rolling process, various contaminants, such as rolling oil, sludge, iron powder from cold rolling, accumulated dust, and welding slag, inevitably remain on the surface. Therefore, thorough cleaning before annealing is necessary to remove these impurities; otherwise, residual oils will form carbon stains during annealing, pollute the furnace atmosphere, affect decarburization efficiency, and may even cause carburization. Additionally, oil residues can deteriorate the surface quality of the steel strip and cause defects like scratches from agglomerates on furnace rollers. The cleaning stage is specifically designed to ensure the cleanliness of the steel strip before annealing.

In the degreasing process, alkaline spraying is the primary cleaning method. Alkaline spraying is a chemical degreasing process that uses the saponification and emulsification effects of alkali to remove grease. Saponification refers to the chemical reaction between grease and alkali in the degreasing agent, producing soap and glycerin, which are soluble in water:

(C17H35COO)3C3H5 + 3NaOH = 3C17H35COONa + C3H5(OH)3

Emulsification involves surfactants in the cleaning agent breaking down the oil film on the steel strip into tiny oil droplets, dispersing them in the alkaline solution to form an emulsion.

During alkaline spraying, high spraying pressure and the presence of surfactants and soaps generate significant foam. Uncontrolled foam reduces cleaning efficiency and can even cause overflow from the cleaning tank, leading to production accidents. Therefore, our plant incorporates defoamers to control foam. After selection, we chose INVINO-3180 silicone defoamer for foam control.

How to use Defoamer in Steel Strip Degreasing?

Addition in Alkaline Solution CirculationTank

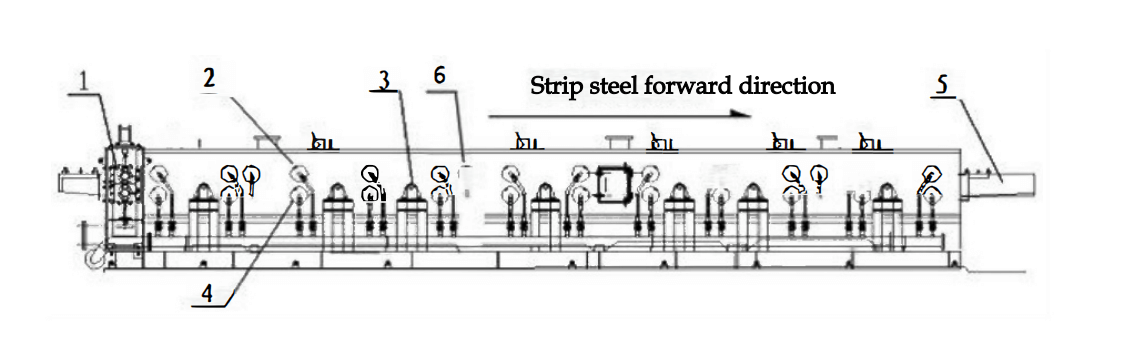

In the degreasing process, the cleaning agentiscontinuously supplied to the alkaline spray andbrush tanks through an alkaline solutioncirculation system,ensuring the cleaning of thesteel strip in the tank (see Figure 1.1).Our plantadds the defoamer quantitatively to the alkalinecirculation tank with the following parameters:

- Cleaning agent flow rate: 8 t/h

- Defoamer INVIN0-3180 flow rate: 8 kg/h

Addition in Alkaline Spraying Tank

This device (see Figure 1.2)sprays alkalinesolution of a certain temperature andconcentration onto the upper and lower surfacesof the steel strip, serving as the first step incleaning the oil from the steel strip surface. Thealkaline spraying device comprises a main tank.sealing rollers, cylinders for opening and closingthe sealing rollers, a spray manifold, and nozzlesThe cleaning effectiveness of this process directlyaffects the subsequent treatment efficiency.

In the later stages of this process, the accumulation of soaps and impurities increases foam formation. Even with defoamer added to the cleaning agent, some foam may still be produced. Therefore, our plant has added several defoamer addition points near the alkaline spray outlets. These are manually added with the following technical parameters:

- Cleaning method: Horizontal vertical spraying

- Alkaline solution temperature: 60-80°C

- Alkaline solution concentration: 3-5% (calculated as NaOH)

- Alkaline solution flow rate: 135 m³/h (maximum)

- Defoamer flow rate: Manually controlled

- Alkaline solution pressure: 0.5 MPa (maximum)

- Number of spray pipes: 24 (12 upper, 12 lower), stainless steel (Ø48×3.5 mm)

- Total number of nozzles: 240 (10 per pipe), flat stainless steel nozzles

- Tank dimensions: Approximately 12.55 m (L) × 2.1 m (W) × 1.54 m (H)

- Tank thickness: Bottom plate 12 mm, side plate 10 mm

- Sealing rollers: Ø250×1600 mm

- Sealing cylinders: Ø160×100 mm, 2 units

- Drive motors: 5.5 kW, 2 units

- Supporting rollers (neoprene-covered): Ø120×2000 mm, 7 units

The Negative Impacts of Foam in Steel Degreasing Processes

While some foam might seem insignificant, excessive or persistent foam during steel strip degreasing can lead to serious operational inefficiencies and quality issues:

Reduced Cleaning Efficiency and Quality

Foam blankets can insulate the steel surface, hindering the cleaning solution’s contact and heat transfer. This results in incomplete oil removal, potentially leading to downstream issues like poor phosphating, uneven coating adhesion, or corrosion defects. Effective foam control is crucial for consistent metal surface treatment.

Equipment Damage and Operational Issues

Excessive foam can cause pumps used for spraying or circulation to cavitate, leading to wear and tear or failure. Foam can also trigger false readings on level sensors, disrupting automated processes, and potentially cause overflows (tank overflow), leading to chemical waste and cleanup costs.

Safety Hazards and Environmental Concerns

Overflows of hot, caustic, or acidic cleaning solutions due to foam pose significant safety risks to personnel. Additionally, excessive defoamer use (if poorly selected) or cleaner drag-out due to foam can increase the load on wastewater treatment systems.

Key Criteria for Choosing Your Steel Degreasing Defoamer

Beyond stability and chemistry type, consider these factors when selecting your metal cleaning antifoam:

- Compatibility: Test the defoamer with your specific degreasing bath chemistry (surfactants, builders, inhibitors) to ensure no adverse reactions occur (e.g., separation, precipitation).

- Efficiency & Persistence: Evaluate how quickly the antifoam knocks down foam and how long it remains effective. Does it prevent foam re-generation under high shear/agitation?

- Dosage Rate: Aim for the lowest effective dosage to minimize cost and potential carry-over.

- Carry-over Impact: Assess the potential impact of any minimal defoamer residue on downstream processes critical to your operation.

- Ease of Use: Consider product form (liquid), viscosity, and ease of dosing (manual or automated).

INVINO Solutions for Steel Processing Foam Control

INVINO understands the demanding environment of steel processing and metal cleaning. We offer a range of industrial defoamers specifically designed for these applications:

- Products engineered for stability in highly alkaline and/or acidic conditions and at high temperatures.

- Both modified silicone defoamer and non-silicone defoamer options to meet diverse process needs.

- Emphasis on formulations offering excellent foam control, good rinsability, and minimal impact on surface quality (low residue defoamers).

- Technical support to help you select the most cost-effective and technically suitable steel degreasing defoamer for your specific line and cleaning chemistry.

Uncontrolled foam in steel strip degreasing is more than an annoyance; it’s a barrier to quality, efficiency, and safety. By understanding the challenges and carefully selecting a stable, compatible, and efficient defoamer – like those offered by YWL Chemical – you can significantly improve your metal cleaning operations and ensure high-quality results for subsequent metal surface treatment steps.