What is the Landfill Leachate Defoamer?

Landfill leachate is the liquid that percolates through a landfill, picking up contaminants along the way. It has a complex composition, containing a wide variety of inorganic and organic substances, many of which are toxic and harmful. The concentration of contaminants in landfill leachate is much higher than that of municipal sewage, which makes its treatment more challenging. To prevent harm to the environment, landfill leachate must undergo strict treatment processes. let’slearn Landfill leachate defoamer INVINO-4000

Challenges in Landfill Leachate Treatment

Landfill leachate treatment typically involves biological processes such as anaerobic biological filters (IAF) and aerated biological systems, often coupled with advanced membrane filtration technologies. Some common treatment methods include traditional activated sludge, biological turntables, and anaerobic fixed membrane bioreactors. The objective of these processes is to filter out suspended solids, harmful molecules, and other contaminants from the leachate.

However, a major challenge during this treatment process is the generation of foam. Foaming during filtration can interfere with membrane filtration efficiency, reduce the effectiveness of the treatment process, and cause operational issues such as clogged filters, increased maintenance costs, and unstable effluent quality.

The Role of Landfill Leachate Defoamer in Treatment

The foam generated during landfill leachate treatment can significantly impact the process, causing both operational difficulties and quality concerns. This is where a high-quality Landfill Leachate Defoamer becomes essential.

A defoamer works by reducing surface tension and breaking up foam bubbles, preventing the accumulation of foam that can obstruct filtration membranes and interfere with the overall treatment process. By adding a defoamer, the treatment process can be made more efficient, and foaming issues can be controlled, ensuring that the leachate is treated effectively.

Application of INVINO-4000 in Landfill Leachate Treatment

At INVINO, we offer a specialized defoamer, the INVINO-4000 which is designed specifically for use in landfill leachate treatment. The INVINO-4000 is highly effective in controlling foam during the membrane filtration process. By adding this defoamer to the system, it helps reduce the foam build-up and improves filtration efficiency. This leads to better overall treatment performance and ensures that the effluent water meets the required environmental standards.

Case Study: INVINO-4000 in Action

One of our customers, a landfill leachate treatment facility, faced significant foaming issues during the membrane filtration phase. The foaming was not only disrupting the filtration process but also affecting the quality of the treated effluent. After evaluating their needs, we recommended the INVINO-4000, which is specifically formulated for landfill leachate treatment.

After the implementation of the INVINO-4000, the customer experienced a noticeable reduction in foam formation. The defoamer helped maintain a smooth filtration process, and the leachate treatment became more stable. The operational efficiency improved, and the effluent water quality also met the required standards for discharge.

INVINO-4000 Landfill Leachate Defoamer

Test Method:

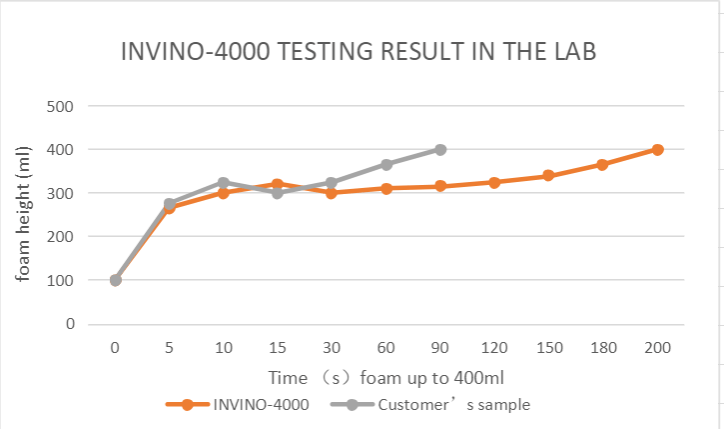

Compare the INVINO-4000 with customer’s sample using air drum in landfill leachate solutions;

- Test temperature: 40 ℃

- Antifoam agent dosage: 1 ml

- Type and amount of test solutions: landfill leachate with 100ml

- Wash the air drum test instrument and add 100ml of garbage leachate. At the set flow rate (double drum head, the flow is opened to the maximum) and temperature, add the defoamer and then turn on the air drum. Record the foam height at different time . The foam suppressing performance of the samples was compared by recording the regularity of the foam volume V over time.

Test Result of Landfill Leachate Defoamer

Under the same conditions, the defoaming speed of INVINO-4000 is faster than that of customer’s sample.

The landfill leachate defoamer is composed of polyether, white carbon black, dispersant and stabilizer; it can maintain a good defoaming effect at a lower concentration. When it is used in the landfill leachate treatment membrane, the damage to the membrane is small, the cost of membrane replacement can be greatly reduced, it will not cause harm to human health, and it has a good degree of integration with most systems. Harmless ingredients.