How to Evaluate Defoaming Efficiency and Compatibility of Antifoam for Paint?

Antifoam for paint plays a crucial role in ensuring the quality and smoothness of paint films. Engineers and manufacturers often evaluate the defoaming efficiency and compatibility of antifoams to select the most suitable product for their applications. This guide will discuss effective methods, including the Foam Height Method, spray coating, roll coating, and system compatibility tests, for evaluating antifoams for paint.

Defoaming Efficiency Test of Antifoam for Paint

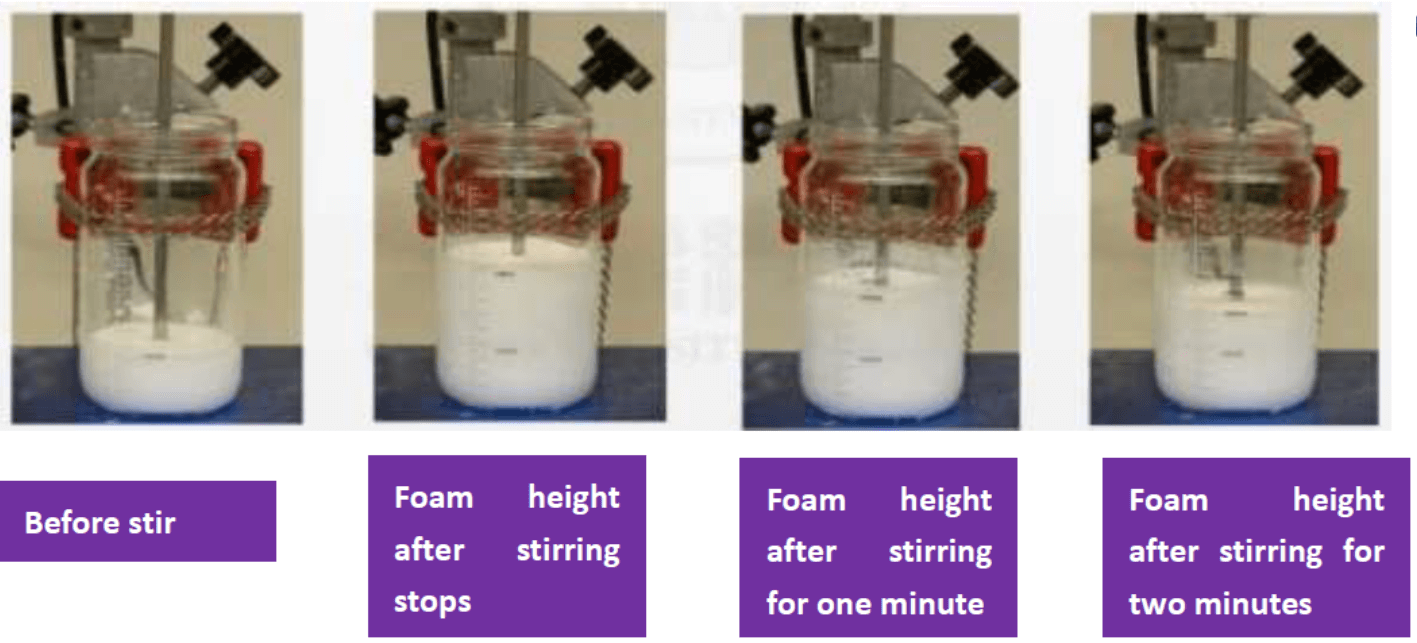

—Foam Height Method for Antifoam for Paint

The Foam Height Method is a reliable way to measure the defoaming efficiency of antifoam for paint. It involves observing the foam reduction capabilities of the defoamer in a controlled test.

Procedure:

- Add a specific amount of paint containing the antifoam into a marked measuring cup.

- Use a micro air compressor to introduce air into the paint system.

- Observe the foam height:

- Higher liquid levels indicate poor defoaming efficiency.

- Lower foam levels suggest better defoaming performance.

This straightforward method helps engineers identify the optimal antifoam for paint based on defoaming efficiency.

It can be used for rapid screening of initial defoamers, and needs to be combined with other test methods such as specific gravity method and roll coating method.

Specific gravity method

The high-speed agitated paint is poured into a density cup, the density of the paint is measured, and then the paint is sealed and stored, and the density is measured after a certain period of time to check whether the density changes.

Spray Coating Experiment for Antifoam for Paint

In this test, a coating agent containing the antifoam for paint is subjected to high-speed stirring and poured onto a polyester film placed at a 25° angle. The surface condition of the dried film is then observed to assess the defoamer’s performance.

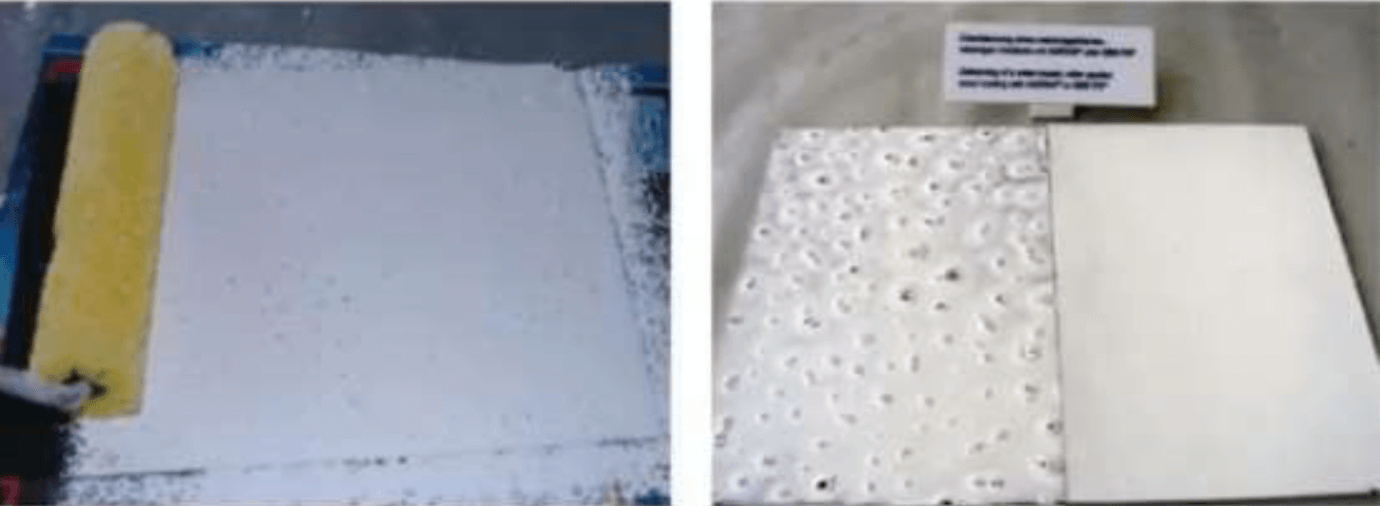

Roll Coating Experiment for Antifoam for Paint

This method involves applying a coating film of paint containing antifoam onto a non-porous substrate using a sponge roller. Observing the dried coating film’s surface condition provides insight into the defoamer’s effectiveness in minimizing surface defects.

Evaluation grade of antifoam for paint

5-No bubbles, 4- very small bubbles, 3 – a small amount of bubbles, 2 – more bubbles, 1 – no bubbles

- Compatibility Test of Antifoam for Paint

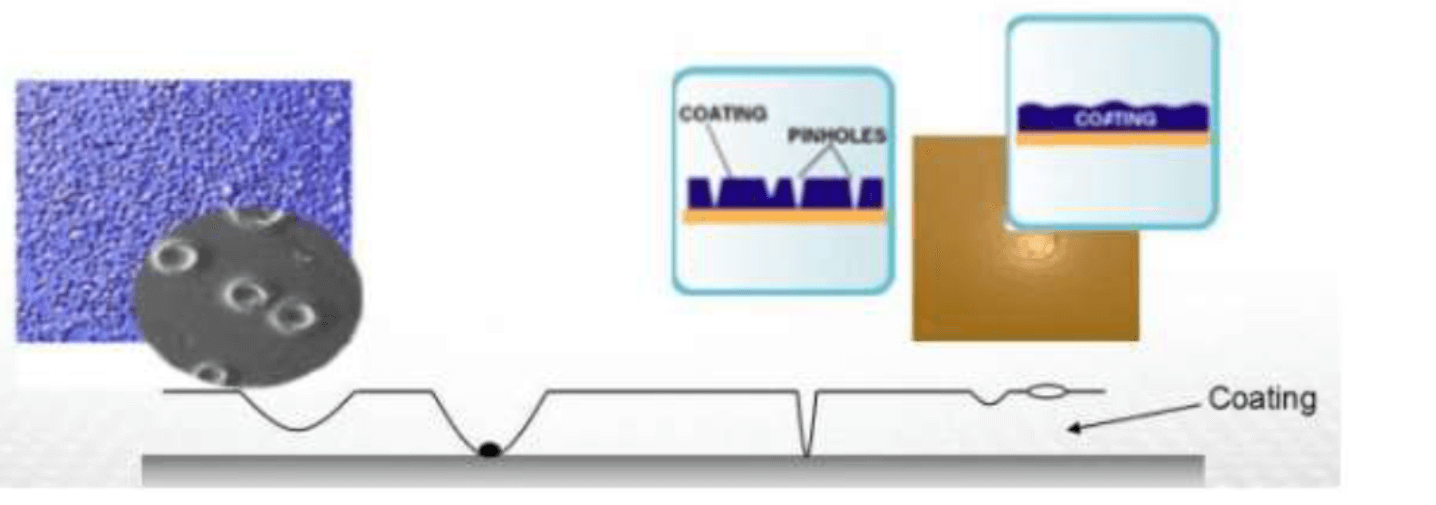

- Scrape Film Test for Antifoam for Paint

This test evaluates the compatibility of antifoam for paint with the coating system.

Procedure:

- Equilibrate the paint preparation for 24 hours.

- Apply a 75 µm wet film thickness paint layer onto a glass plate.

- Observe both the wet and dried film surface conditions for defects.

Common Paint Film Defects:

- Shrinkage: Circular pits of varying sizes on the dried film.

- Fisheye: Small particles within circular pits resembling fish eyes.

- Pinhole: Small holes caused by trapped air bubbles.

- Orange Peel: Uneven surface resembling orange skin.

Rating Scale (0-5):

- 0: No film defects.

- 5: Severe defects, including shrinkage, fisheyes, pinholes, and orange peel.

Paint film defects:

Shrinkage: the phenomenon of a number of circular pits with different sizes and different distributions after the paint film is dried.

Fisheye: There are particles in the circular pits on the surface of the paint film, which is like a “fisheye”.

Pinhole: A morbidity in the paint film that resembles a pinhole. It is caused by the air bubbles mixed in the wet paint film and other air bubbles generated, which cannot be leveled before the paint film dries.

Orange peel: The paint film has a surface-like appearance of orange peel.

Rating / 0 ~ 5 :

0 = no film defect

5 = serious paint film defects, such as local shrinkage of the paint film, pits, shrinkage holes,orange peel and other defects.